The Cladinox Process

The Cladinox process is based on experience developed over a period of forty years. It is a significant improvement on A. Cacace’s USA patent (2004) no: 6,706,416, which is believed to be the only technology to date to have successfully produced stainless-clad bars commercially. More than 2000 tons have been produced in the UK and sold into the USA.

The Cladinox process represents a breakthrough for the steel industry because of its “rolling-mill friendly” technology, which enables stainless clad billets to be manufactured which:

- are square, or of any standard shape, and of the required lengths for a rolling mil

- have a solid carbon steel (continuous-cast) billet as core and can therefore meet any international specifications required for tensile and other characteristics

- have cladding made of lean duplex, austenitic or other stainless steel grades

- do not require specialist and highly capital intensive billet-manufacturing plant

- can be heated in standard pusher-type or other gas/oil-fired or induction heated furnaces

- are hot-rolled preferably in modern in-line rolling mills or through cross country mills, with conventional roll-pass designs

- result in a much more even and potentially lower percentage cladding (<15%) than previously possible

- result in a consistent and “perfect” metallurgical bonding between core and cladding along the entire length of the finished product, much superior to that of previous technologies

The Cladinox technology can also be applied to cladding alloys other than stainless steel to achieve optimal properties more economically such as appearance or corrosion or wear resistance for the cladding, combined with desirable core properties such as high tensile strengths and lower costs. For example, nickel-chrome or copper-nickel alloys can be used as cladding materials. Cladinox billets can be prepared for trials to suit potential licensees’ rolling mills.

What is Cladinox?

In the simplest of terms Cladinox is a stainless steel clad carbon core which has been hot rolled to produce an impeccably bonded steel; this bonding is truly revolutionary.

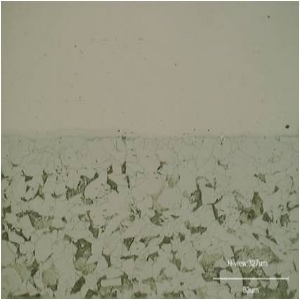

Even partially hot-rolled Cladinox shows a strong metallurgical bond between core and cladding: demonstrated microscopically by the “Kirkendall Effect”: the atomic inter-diffusion of the carbon core into the stainless steel cladding and vice-versa across their common interface. The interface or “bond” containing both materials in its lattice structure grows during hot rolling and spans some 110 microns (0.11mm) in the finished product.

This “new material” at the interface is actually stronger than the stainless steel itself because of the stronger carbon steel atoms now contained. It means that Cladinox can never de-bond such as sometimes occurs with conventionally clad plate during heat treatment or during welding.

Metallography, Interface and Bond Strength Tests

1. Metallography and Interface

CLADINOX'S METALLURGICAL BOND: “The Kirkendall Effect” – “Solid State Fusion”

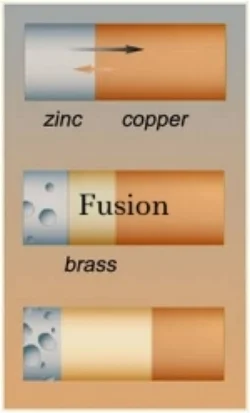

- Across an “intimate” & inclusion-free interface of 2 solid metals; atoms diffuse between each other at different rates, with heat, pressure & time. For example, brass, which is zinc & copper’s alloy, grows in the direction of the faster diffusing species.

- Thereby creating a metallurgical bond between the 2 solid metals whose integrity or “strength” depends on the “cleanliness” of the interface between the 2 metals and on the atoms comprising this “Transition Zone” or bond.

- Because hi-tensile CS is stronger than austenitic SS, the Transition Zone is therefore stronger than SS.

- Cladinox’s unique scavenging/vacuum-forming technology creates the ideal inclusion-free interface conditions between CS & SS, across which atomic diffusion can occur to result in a perfect metallurgical bond.

Even Stainless Steel Cladding

Cladinox Re-Bar Hot Rolled by USA Steel Major, Bent According to AASHTO MP13 04 (2006) & Sectioned Showing No De-Bonding

Inclusion Free Interface = Perfect Bond

2. Bond Shear Strength Tests

Cladinox section through conventional box roughing passes starting from a square stainless clad billet:

- Despite having been rolled through only 6 passes the shear bond strength tested showed “perfect” bonding, by almost equaling the stainless steel cladding's ultimate shear stress of 480MPa, with a cladding/core interface bond stress averaging 460MPa.

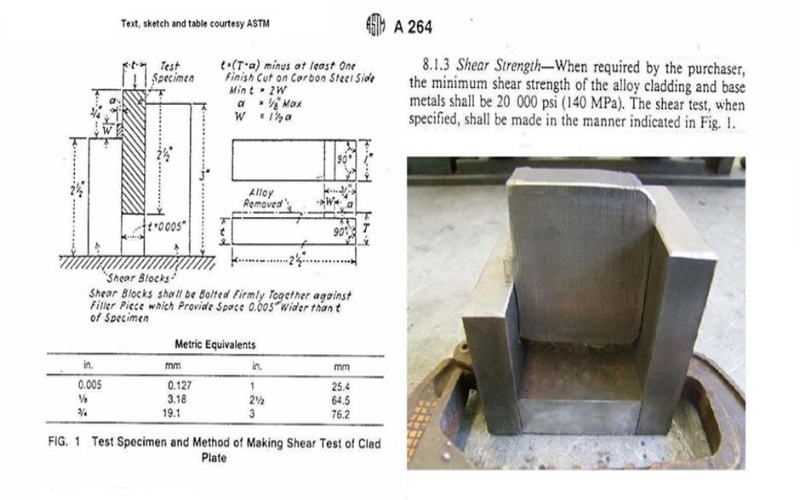

- Its shear strength is furthermore well in excess of the minimum requirement of 140 MPa specified in the AASHTO MP 13M/MP 13-04 Standard Specification for “Stainless Clad Deformed and Plain Round Steel Bars for Concrete Reinforcement”.

The AASHTO MP 13M/MP 13-04 Standard Specification (please click to link to info regarding this) "Stainless Clad Deformed and Plain Round Steel Bars for Concrete Reinforcement" requires a minimum bond strength in shear of 140MPa when tested according to ASTM A 264 - the specification for stainless chromium-nickel steel clad plates.

An accredited testing laboratory conducted tests on two sections of a Cladinox rolled square in accordance with the ASTM A 264 indicated methodology.

CLADINOX SCR IS HOT ROLLED THROUGH 18 ROLLING PASSES FROM A 6” CLADINOX BILLET.

Cladinox specimens from stock rolled through initial passes & prepared according to ASTM 264-12 for Stainless Clad Plate; exhibited Bond Shear Strengths (BSS) almost equivalent to SS’ shear strength (SS) despite after only 1,5% of total deformation

470MPa Bond Shear Strength = 98% of Solid SS Shear Strength of 481MPa when Tested According to ASTM 264-12 for Stainless-Clad Plate – A Perfect Bond

Cladinox Bond Shear Strength Characteristics According to ASTM A 264

- Shear Stress Curve for Sample 1 showing an ultimate shear stress of 303 MPa. Note ductile fracture characteristics from curve.

- TABLE - COMPARATIVE RESISTANCE TO SHEARING IN DIES - TYPICAL VALUES

- Shear Stress Curve for Sample 2 showing an ultimate shear stress of 319 MPa. Note ductile fracture characteristics from curve.

Classical Cup-Cone Fracture and No De-Bonding during Tensile Testing